Analysis of Structure and Parameters of Qingdao Nanchen Turntable Type Shot Blasting Machine

In the field of global industrial surface pre-treatment, the Q35, Q36 and Q76 series turntable type shot blasting machines developed by Qingdao Nanchen Intelligent Equipment Technology Co., Ltd. are the preferred equipment for the surface treatment of steel structural parts, castings and other workpieces. Widely applied in various industries, these machines provide integrated solutions for derusting, surface strengthening and other related processes.

Centered on the working principle of "turntable rotation + shot blasting and projection", these machines feature a high-precision turntable that ensures uniform force distribution on the workpiece surface. The core components are made of wear-resistant alloy steel, with the shot recycling rate exceeding 99%. The processing efficiency is 30% higher than that of traditional equipment, achieving energy conservation and environmental protection, reducing consumable costs, and avoiding workpiece damage, thus laying a solid foundation for mass production.

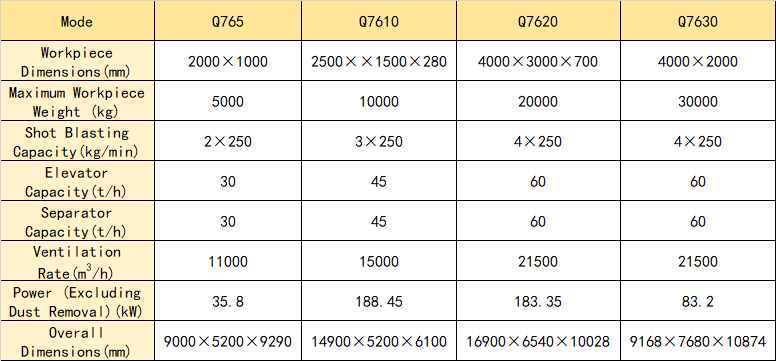

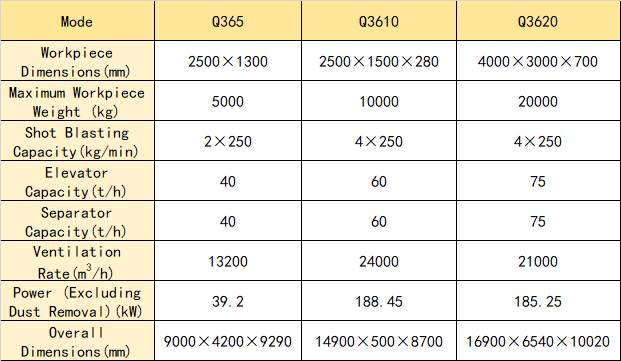

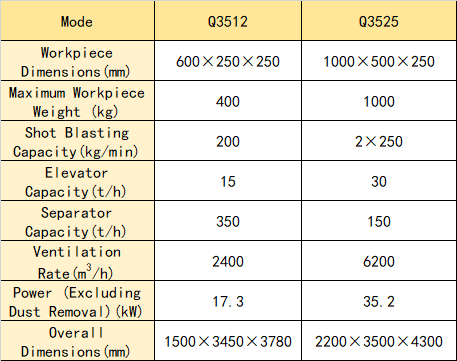

The series of turntable type shot blasting machines includes a variety of models with comprehensive specification coverage, meeting the processing requirements under different working conditions. The workpiece processing weight ranges seamlessly from 400kg to 30000kg. Among them, the Q3512 model is suitable for small workpieces, with a maximum processing weight of 400kg and a workpiece size of 600×250×250mm; while the Q7630 model is specially designed for large and heavy-duty workpieces, with a maximum processing weight of 30000kg and an overall dimension of 9168×7680×10874mm, capable of handling the surface treatment of super-large components. In terms of performance parameters, each model has its own focus: the shot blasting capacity ranges from 200kg/min to 4×250kg/min; the hoist and separator of the Q3620 model both reach a capacity of 75t/h, ensuring efficient operation and material circulation; the ventilation volume covers 2400m³/h to 24000m³/h, which can effectively discharge operational dust and optimize the working environment; the power (excluding dust removal) ranges from 17.3kW to 188.45kW, which can be flexibly selected according to production scale to achieve a balance between energy consumption and efficiency.

Modular structural design is a major highlight of this series of shot blasting machines. The equipment can be flexibly combined and configured according to customers' production needs, which not only meets the demands of standardized mass production but also adapts to customized processing scenarios. With a high level of intelligent operation, the equipment is easy to master and can be put into use without complex training, reducing labor costs and operational thresholds. Whether it is the processing of heavy castings or the strengthening of precision components in the mechanical casting field, this series of shot blasting machines can complete high-quality surface pre-treatment operations with stable performance and precise processing effects.

The Q35, Q36 and Q76 series turntable type shot blasting machines boast both excellent performance and flexible adaptability. Relying on the advantages of modular design, we can provide exclusive customization according to customers' actual production needs and create efficient and reliable surface treatment solutions for them. Meanwhile, Qingdao Nanchen builds a solid guarantee for customers with a full-life-cycle service system, providing on-site installation, operation training and lifelong maintenance services, with a professional team offering 24/7 response. We also provide supporting supply of affordable spare parts, technical follow-up visits and solution optimization, fully guaranteeing the stable operation of the equipment, and empowering the quality improvement and efficiency enhancement of the global industry through both superior product quality and high-standard services.