Choose the Right Z94 Series Core Shooter for Your Factory in 60 Seconds

The Qingdao Nanchen Z94 Series double-station vertical parting hot box core shooter is specially designed for the molding of small and medium-sized sand cores in the global automotive, engineering machinery and other fields, and can meet the working condition requirements of different factories worldwide. To quickly select a model that fits your actual needs, you can focus on the following three aspects, and lock in the right model in just 60 seconds.

1. Sand Core Specifications

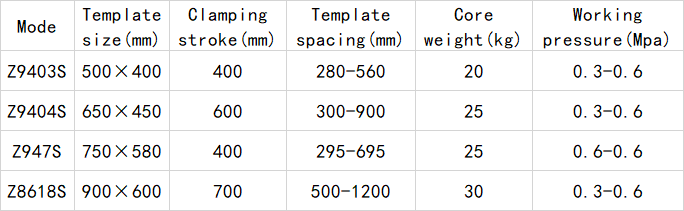

Sand core specifications are the foundation of model selection, and different models of core shooters correspond to specific sand core size and load capacity ranges: For producing small-sized sand cores with a weight of no more than 20kg, the Z9403S (mold plate size: 500×400 mm) is an ideal choice, with a mold plate spacing of 280-560 mm and a clamping stroke of 400 mm, which can meet the molding needs of conventional small and medium-sized sand cores; For sand cores weighing about 25kg, the Z9404S (mold plate size: 650×450 mm) or Z947S (mold plate size: 750×580 mm) is optional. The former has a clamping stroke of 600 mm and a mold plate spacing of 300-900 mm for better spatial adaptability, while the latter maintains stable load-bearing performance; For large-sized sand cores with a weight of no more than 30kg, the Z8618S (mold plate size: 900×600 mm) is available, with a clamping stroke of 700 mm and a mold plate spacing of 500-1200 mm, which can meet the molding requirements of larger sand cores.

2. Production Scenarios

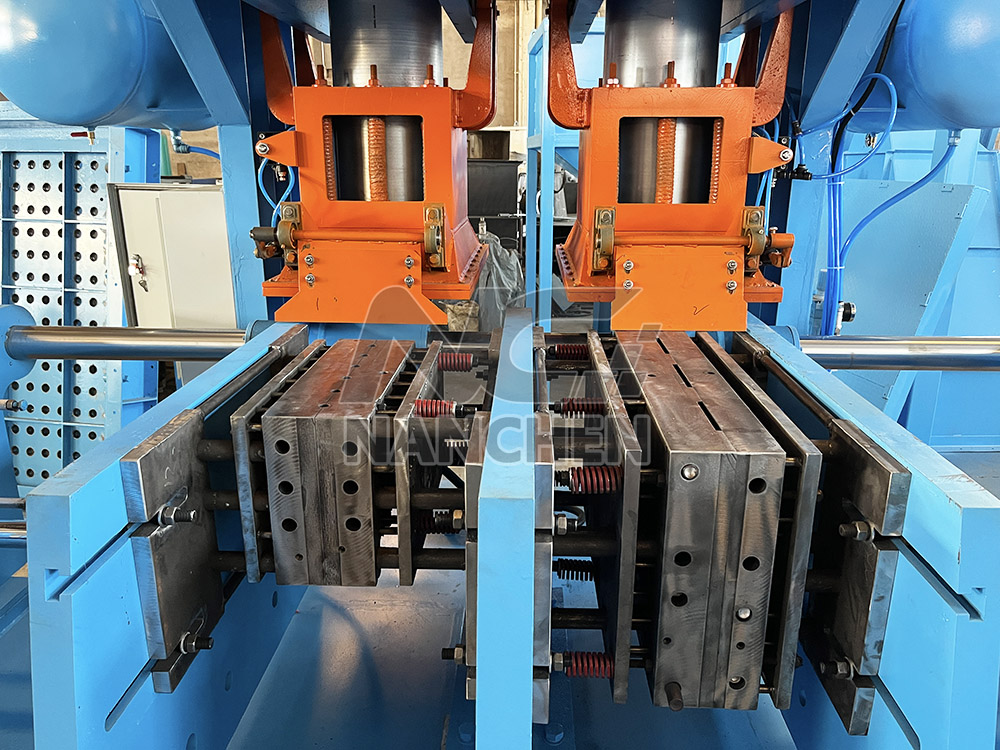

This series of hot box core shooters features a double-station structural design, which can be equipped with two sets of molds at the same time and support the setting of different working parameters. It enables both independent production at a single station and simultaneous operation at two stations without mutual interference, increasing production capacity by 50%-80% compared with single-station equipment. If the factory needs mass production of a single type of sand core, the simultaneous operation of two stations can greatly boost output. If it involves switching between multiple types of sand cores, the independent parameter setting of the two stations can reduce the mold change and adjustment time, making it particularly suitable for multi-batch and small-batch production scenarios.

3. Working Conditions

Targeted optimizations have been made to this series of core shooters for the factory working conditions in different regions: The core components have the characteristics of low temperature resistance and dust proof performance, enabling stable operation even in harsh workshop environments; The compact body layout is suitable for workshop planning with limited space; The working pressure ranges from 0.3 to 0.6MPa, which can adapt to the air pressure conditions of most factories worldwide; Meanwhile, the equipment complies with the mainstream global safety and environmental protection standards and supports customized adjustments, ensuring seamless adaptation to local production specifications and workshop conditions.

In summary, you can quickly select the Z94 Series core shooter suitable for your factory and achieve efficient and stable production by first locking in the model according to sand core specifications, then planning the usage mode based on production scenarios, and finally making customized adjustments in accordance with working conditions.