Qingdao Nanchen L25 Series Conveyor Type Vibrating Shakeout Machine

The L25 Series Conveyor Type Vibrating Shakeout Machine is a special equipment for the shakeout and separation of small and medium-sized castings in the foundry industry. It is compatible with manual molding, mechanical and semi-automatic molding processes, enabling efficient separation of molding sand, sand boxes and castings. In addition, its conveyor-type design supports self-unloading of castings, providing strong support for the continuous production of foundry workshops.

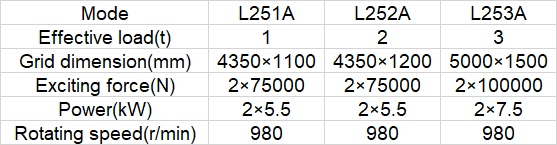

The L25 Series Conveyor Type Vibrating Shakeout Machine includes three models: L251A, L252A and L253A, with an effective load range of 1-3 tons, which can meet the production needs of customers with different production capacities worldwide. The equipment features stable and controllable rotation speed to ensure a uniform and efficient shakeout process, and its load and power configuration adopt a gradient design, allowing flexible model selection according to the batch of castings. The grating, a core component, is quenched with excellent wear resistance, and its dimensions are optimally adapted to different models. It can efficiently crush sand lumps and guide the smooth conveying of sand materials, ensuring an uninterrupted production process.

Thanks to its high-quality core configuration, the L25 Series Conveyor Type Vibrating Shakeout Machine has a 30% higher efficiency than traditional shakeout machines, greatly shortening the production cycle; its molding sand recovery rate exceeds 85%, reducing molding sand waste and raw material costs. Adopting a synchronous force transmission structure, it avoids lateral resonance, and with the matching shock absorption device, it exerts small impact force on the ground, solving the problems of unstable operation and easy foundation damage of traditional equipment. Meanwhile, the vibration motor is fastened with high-strength alloy steel bolts and lock nuts, and an additional wedge tightening mechanism is added to eliminate the risk of bolt shearing, complying with the safety and environmental compliance requirements in many regions around the world.

This shakeout machine has a wide range of application scenarios covering the core processes of foundry workshops. It can be stably adapted to the shakeout of scattered castings in manual molding lines, the post-processing of batch casting in mechanical and semi-automatic molding lines, as well as the shakeout operation of high-temperature sand molds. It is especially suitable for manufacturers of small and medium-sized castings pursuing high-efficiency and low-consumption production, and can be flexibly commissioned according to different production modes.

The equipment supports one-button start and is easy to operate without complicated training; its maintenance cost is 20% lower than the industry average, reducing late-stage operation investment. In addition, the L25 Series Conveyor Type Vibrating Shakeout Machine can be customized according to users' specific production needs. Qingdao Nanchen has a professional technical team to provide after-sales support, and offers a full-process solution from equipment model selection to production adaptation for global customers, helping them improve production efficiency and achieve stable and continuous production.